Add to Cart

Quick Details

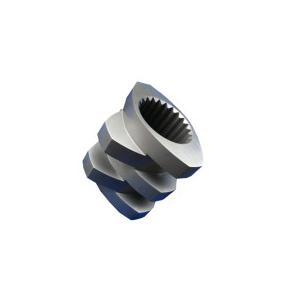

Product Name:Melting Zone Triple Screw Extruder Screw Elements 30° - 90° Angle Design Stable Performance

Material: 6542/Tool Steel/38CrMOAla/HIP

Color: Metal

Exprience:20 years

Packaging: Wooden Box or Paper Box According to your order

Lead Time: 5-60 days

Product Description

Screw elements are the core components of triple screw extruders, directly influencing the quality and output of plastic products. Our high-quality screw elements ensure efficient mixing, cutting, dispersion, and interaction of plastic molecules. The outstanding self-cleaning capability guarantees the overall performance and quality of the production line. Drawing on years of experience and integrating advanced international techniques along with customer feedback, our company has developed a wide range of optimized screw elements. These are designed with precise parameters to achieve excellent self-cleaning, wear resistance, and corrosion resistance, meeting diverse processing needs effectively.

We can satisfy your different material needs:

According to appearance design,

Covey Screw Segment,Mixing Screw Segment,Kneading Block&disk,Transition Screw Element,Deep groave Transfer Element,Screw Element for side feeder,1/2/3-flighted Screw Element,OEM Special Screw Element.

|  |  |

| 1-flighted | 2-flighted | 3-flighted |

|  |  |

| KB 30° | KB 45° | KB 60° |

|  |  |

| KB 90° | SK | DISK |

According to Materical,

-For wear application:

Tool Steel:W6Mo5Cr4V2

PM-HIP material:WR5,WR13,WR14,CPM10V,CPM9V.

-For corrosion application:

38CrMoAla

PM-HIP material:WR4,WR13,WR14,CPM10V,CPM9V.

-For wear and corrosion application:

PM-HIP material:WR13,WR14,CPM10V,CPM9V.

-Other materials:

Stainless Steel:316L,440C etc.

Through the understanding of customers,recommend the most valuable material.

Tool Steel

| W6Mo5Cr4V2 Chemical Composition | |||||||||||

| C | SI | Mn | P | S | Cr | Mo | V | W | Cu | Ni | |

| W-% | 0.88 | 0.35 | 0.3 | 0.023 | 0.003 | 4.03 | 4.81 | 1.86 | 5.95 | 0.12 | 0.24 |

Production Process

| NO.1

Workblank

Select high-quality raw materials

|

| NO.2

Piecewise

|  |

| NO.3

Hit bottom hole

|

| NO.4

Machining thread

|  |

| NO.5

Finish machining thread

|

| NO.6

Threading grinding

|  |

Our Service

| 24-hour Hotline

No matter when and where to call we can find our service to you.

| Pre-sales Consultation

We have five sales people online, and whether you have any question can be solved through online communication,welcome your consultation. | After-sales Services

Receive products have any questions about the product, can look for us,we will help you deal with the the first time,to your satisfaction. |

|

All ZT keep pay attention to every step of the details,We are looking forward to the forge ahead together with you!

| ||

Packing&Delivery

Packing Details: According to your order quantity packaging,shipping wooden boxes,air carton.

Delivery Details: 5-40days after order.

|  |  |

| 1.Rust-proof oil processing, Prevent rust in transit. | 2.Oiled paper packages, Prevent oil dry. | 3.Bubble wrap package, Prevent collosions. |

|  |  |

| 4.Special foam packaging. | 5.Packing | 6.Sealing |

OUR COMPANY

| NANJING ZHITIAN is specialized in the manufacturing of Replacement Parts for Twin Screw Extruder.Manufacturing Barrels,Gearboxes,Overall Liners for Twin Screw Extruder. We also provide you the refurbishment service for barrels and Gearboxes.In addition to providing high quality spare parts for domestic twin screw models,we can offer the replacement parts for a variety of twin screw extruders made in Europe ,America ,Japan ,Korea ,etc.

My company with strong technical force,excellent processing equipment,advanced production technology,strict inspection system and perfect after-sales service,praised by customers.Since my company's products have been mature application in Leistritz,Coperion,Berstorff,JSW,Toshiba,Jwell,Steer and other well-known brands.

All ZT keep pay attention to every step of the details,we are looking forward to the forge ahead together with you! |

|

FAQ

How long does it take to get my products since I paid for them?

---According to yout order quantity,we will give you a reasonable delivery date.

Can I get the warranty of one year for free?

---If you need the warranty,you should pay for it.If not,do not worry ,we have confidence in our products.

How is your after-sale service?

---You will get our help in time as long as you find something wrong about our produces.Believe us,you deserve the best.

Are yuo responsible for the assembly?

---We will provide this service at your requst.